The production of enriched fractions from material mixtures is an important step in the process chain for the processing of primary and secondary raw materials. In addition to established physical classification and sorting processes, intelligent solutions are increasingly in demand here to cope with the growing complexity and heterogeneity of material flows. This is exactly what our modular sorting plant offers: it enables the successful recycling of a wide variety of waste – for a sustainable circular economy and the reuse of high-quality raw materials.

The future of recycling: our unique modular sorting plant

Areas of application

The areas of application are diverse and range from the sorting of electronic waste and metals to the separation of mixed plastics into different types. This creates the conditions for material-specific recycling and increases the market value of the material flows. The sorting plant is suitable for basic investigations into the sortability of material flows as well as for the processing of large quantities.

In addition to enriching recyclable materials in specific fractions, the removal of harmful substances is one of the most important objectives of sorting.

Modularity

Thanks to its modular design, the various sorting units in our plant can be flexibly combined and individually configured. This enables us at Fraunhofer IWKS to simulate a wide variety of sorting processes on an industrial scale and develop new methods for practical application. This flexibility and versatility distinguishes our sorting plant from conventional plants in Germany.

With the help of AI, we find the most economical and ecologically sensible recycling path for every waste component – for a closed recycling loop.

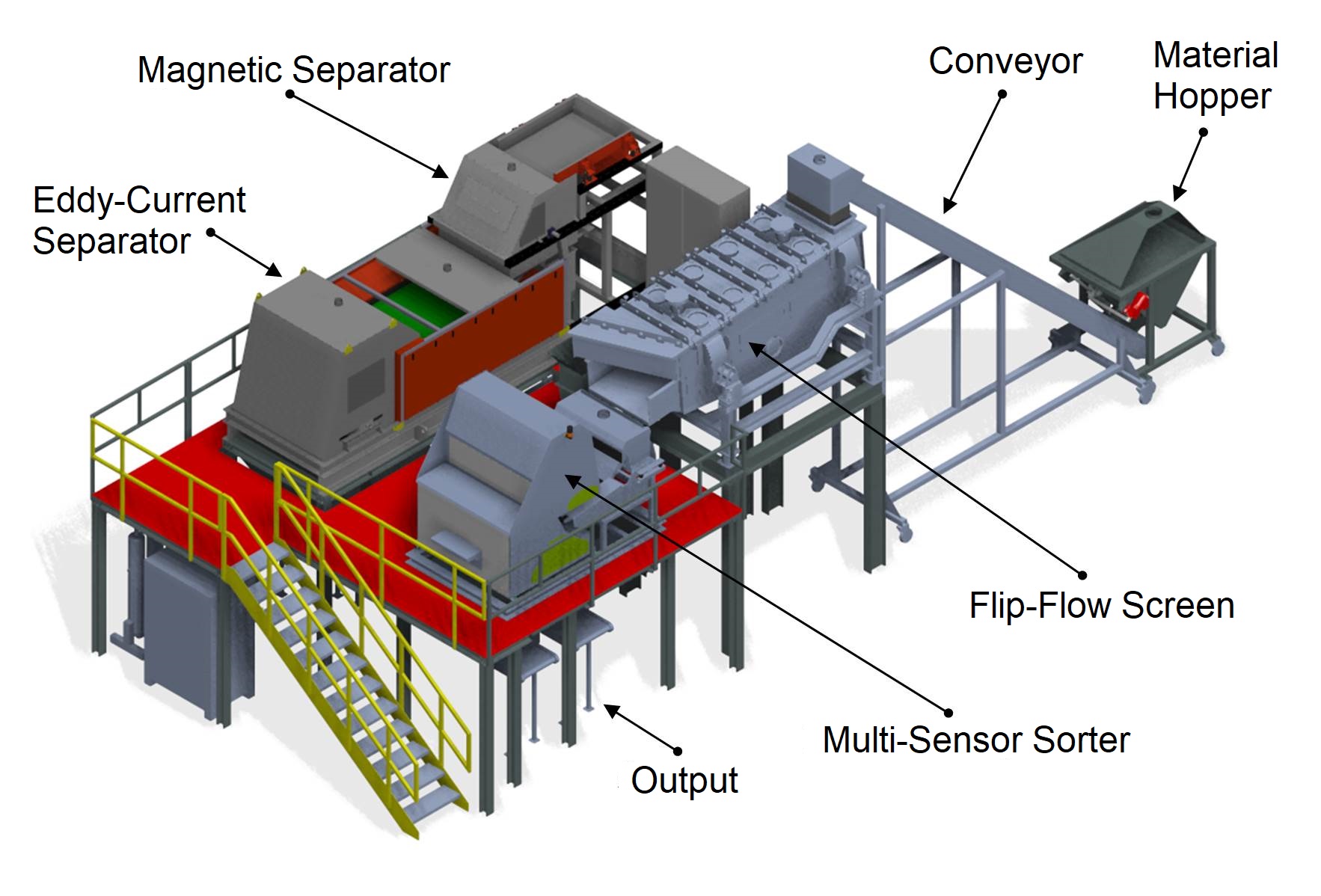

The modular concept comprises the following units in detail:

Flip-flow screen (Spaleck)

- Screening of difficult, like sharp-edged and snagging materials with screen cuts

- “Trampoline effect” creates accelerations of up to 50g in the screening mats

- Very good loosening up of the product, no clogging

Magnetic drum and eddy current separator (Eriez)

- Adjustment of process parameters through variation of rotation and belt speeds and positions of pole wheels

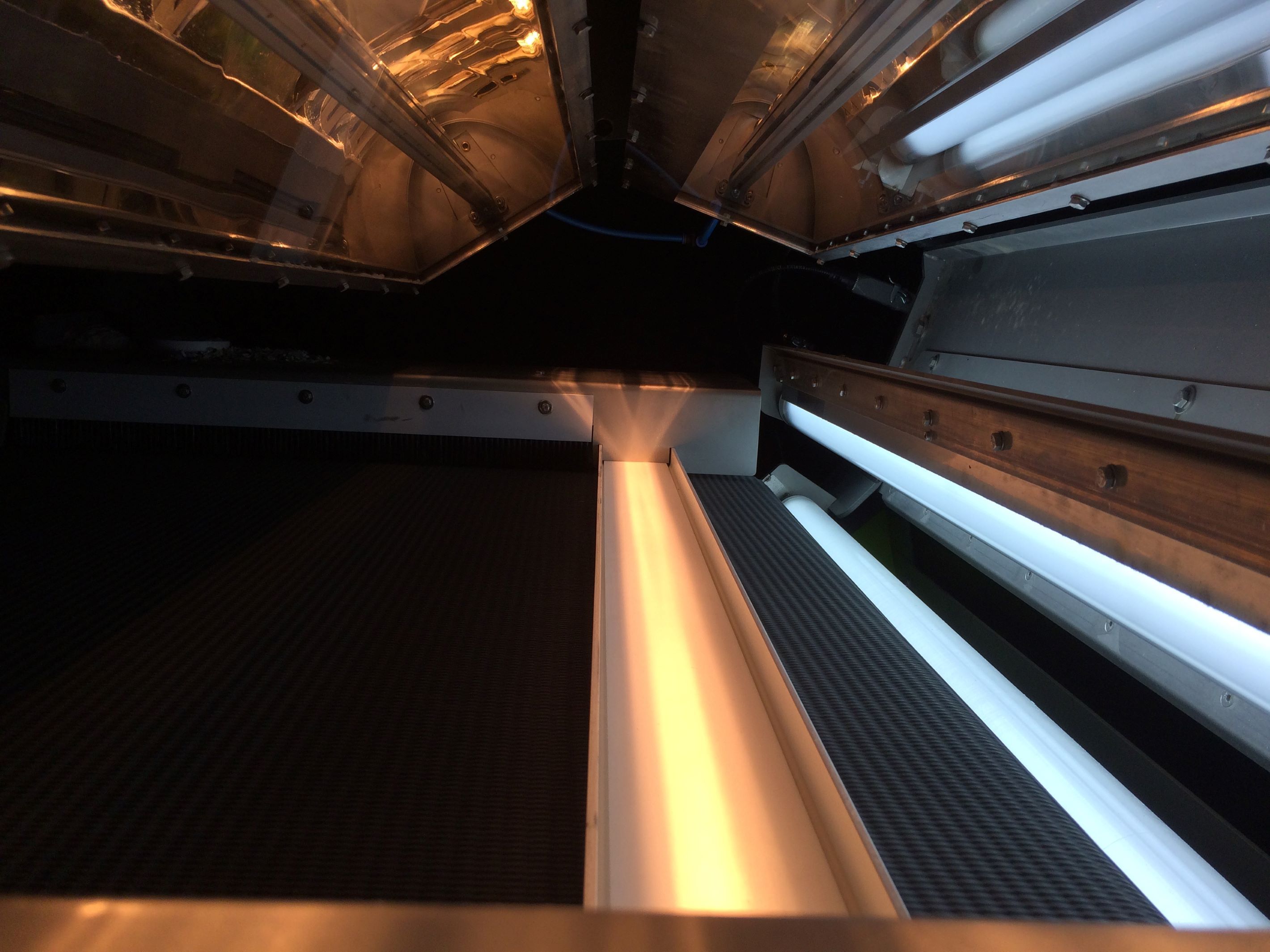

Multi-sensor system (Sensotec)

- Combination of 2 CCD line cameras (color and shape of objects), Induction sensor (detection of metals), Hyperspectral camera (NIR 1330-1900 nm, identification of organic materials)

- Compressed air ejector

Zigzag air separator (Venti Oelde)

- Used for classification, for example for dedusting material, but also for sorting light materials or objects with a large surface area, such as foams and films.

Innovative sorting technology

In close cooperation with manufacturers and as part of publicly funded projects, we are constantly developing the sorting technology used in our annex: through the targeted use of digitalization and AI.

These optimisations give us numerous advantages:

- Collection and evaluation of process and machine data

- Object recognition using colour cameras

- Improved material recognition in the near-infrared range

- Based on the data collected: Evaluation of processes and process chains from an economic and ecological perspective (ecological balance, life cycle assessment)

These advances enable sorting processes to be made smarter, more efficient and more sustainable. Our goal is to determine the optimal recycling path for every waste fraction.