EIT Raw Material project reduces the content of critical raw materials in permanent magnets

Towards the reduction of critical raw materials in permanent magnets to facilitate and accelerate the European energy transition.

The discovery of high performance Neodymium Iron Boron (NdFeB) magnets, almost 40 years ago, revolutionized the design of electromagnetic motors, generators and actuators. With the highest magnetic performance nowadays available, they enable the miniaturization of various systems. Today they are key components of a range of devices including gearless wind turbines, electric and hybrid-electric vehicles, electric bicycles, hard disk drives and air-conditioners. The demand in this high technology products is growing fast to accelerate the European energy transition. However, the rare earth reserves, Neodymium and Dysprosium used in these magnets, are currently monopolistically supplied by China. It is therefore of major importance to make efficient and sustainable use of the rare earths, and at the same time take full advantage of these powerful materials.

Within the perspective of limited critical raw materials, UPGRADE project’s main objective is to provide new NdFeB alloys with an appropriate microstructure for the manufacturing of high performance NdFeB permanent magnets, while reducing the content of critical rare earths such as dysprosium or neodymium. The NdFeB alloy is currently obtained by quenching the melted alloy on a cooled, rotating wheel, also called Strip Casting. This process allows obtaining a fine microstructure well adapted to the subsequent steps of the manufacturing of NdFeB magnets by powder metallurgy. The main goal of the project is to establish the process parameters as well as optimum alloy composition that will allow the refinement of the microstructure of NdFeB alloy and enable the production of sintered magnets while saving critical raw materials. First results of the project demonstrated that a reduction by almost 40% of dysprosium content in the magnets could be possible, at laboratory scale, by adjusting the composition as well as the manufacturing process parameters of the starting alloys. The next step of the project will be the implementation of these results at industrial scale.

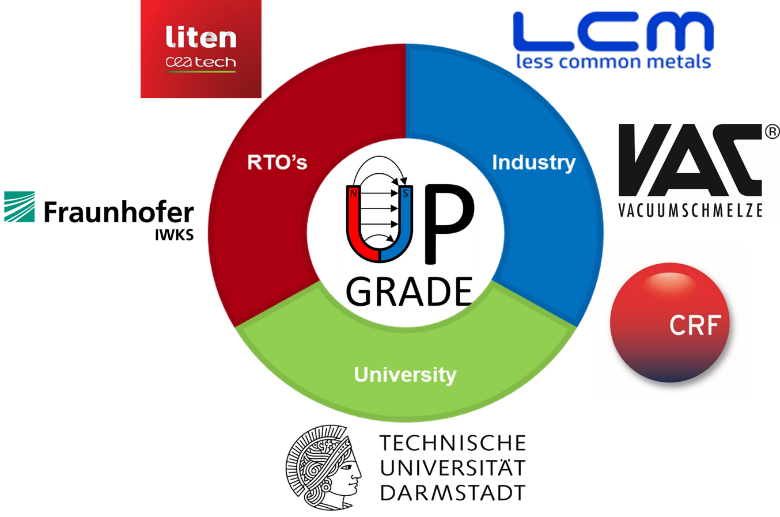

Partners originating from 3 different European countries cover the full value chain, from alloy manufacturing (Less Common Metals, UK) to the magnet manufacturing (Vacuumschmelze, DE) and performance assessment (Centro Ricerche Fiat, IT). Two research institutes (CEA-Liten, FR, and Fraunhofer IWKS, DE) and one university (Technische Universität Darmstadt, DE) provide their magnet expertise by developing the laboratory scale process in the consortium.